AI in CNC machining — that may be, employing artificial intelligence within the CNC machining approach — feels normal, doesn’t it?

AI can revolutionize quite a few areas of your functions apart from the machining itself. Think about using algorithms to improve scheduling and useful resource allocation.

This automated advice not just accelerates the set up time, but also enhances the accuracy with the machining process. For manufacturers, This implies enhanced efficiency, reduced programming time and even more consistent portion quality.

Used CNC lathes have a lot of possibilities to improve them for that production of various types of parts. For example, youll require to look at:

CKA sequence automatic cnc lathe is 2 axis cnc lathe processes of cutting for all kinds of shaft parts. This machine could approach diverse interior bore, ex-circle, round conical area and screw thread, especially well suited for the small and middle sized shaft and plate function piece from tough processing to finish processing in batch.

Although CNC machines execute the operations, it’s the CAM software that orchestrates your entire method. This software package will be the unsung hero, bridging the hole between design and style and production.

Mistake Detection: AI can forecast potential collisions or Device deflections, creating alerts just before injury happens.

Whether or not you are hunting for the best equipment or seeking to deepen your comprehension of the More machining method, CNCMachines.com can be your go-to resource. Be part of us as we carry on to help innovation and excellence in CNC machining, when constructing powerful partnerships through the production community.

Aerospace and Automotive: MultiCam CNC machines are revolutionizing the aerospace and automotive industries by enabling intricate parts to get crafted with unparalleled accuracy.

Following the proposed ANN-ITWP system were founded, 9 experimental screening cuts were being done to evaluate the performance of the system. With the check benefits, it absolutely was evident the system could predict the Device wear online with a median error of ±0.037 mm. Experiments have proven which the ANN-ITWP system can detect Instrument use in three-insert milling functions online, approaching a real-time basis.

Explore how AI is revolutionizing American producing by boosting toolpath optimization, predictive upkeep, and supply chain organizing. Discover the main advantages of clever CNC machining and predictive analytics in modern factories.

Development definitely received’t be immediate, and a lot of outlets will need time to include alterations to their production procedures, but those that do will experience the benefits. Finally, anything is shifting towards IoT and AI incorporation.

Buying AI-driven CNC solutions is essential for manufacturers wanting to leverage these developments. By adopting AI technologies, businesses can achieve important operational advancements, cost financial savings in addition to a aggressive edge inside the at any time-evolving producing landscape.

Woodworking: Woodworkers depend on modern CNC machines to speedily, properly and precisely craft an array of wood objects. From cupboard earning and home furniture setting up responsibilities to generating intricate carvings or thorough engravings, MultiCam CNC may be the go to technology for these industries.

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Katie Holmes Then & Now!

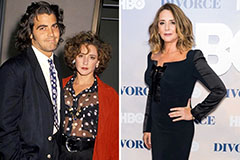

Katie Holmes Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!